Thanks for visiting our gallery page.

Here you will find pictures that highlight our casing jack's unique features and versatility.

freeing stuck production slips is easy with our casing jacks

We've seen it time and time again. Once a customer uses our casing jacks to pull stuck slips, they never want to risk over pulling with a rig.

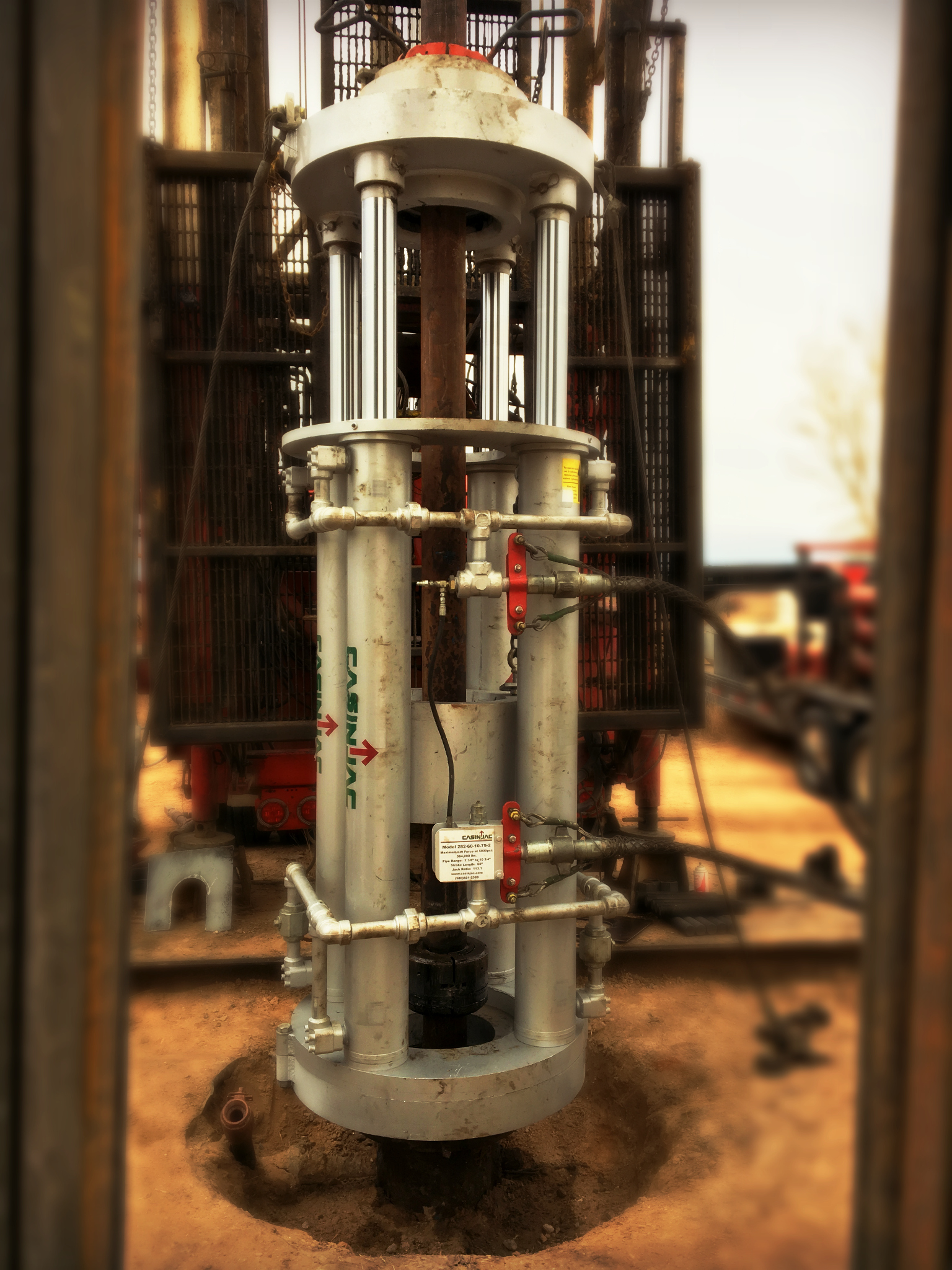

Model 282 casing jack's small foot print

Our casing jacks are designed to fit directly on the well head flange. This means a small foot print, no need for beams, and the versatility to be down in a cellar, up on a BOP or set on a drilling rig floor.

Model 282 casing jack mounted on BOP with optional work basket

Detail of the Model 282 work basket

The work basket attaches to the top of the cylinder mounting plate and allows the traveling head of the jack to continue to move independently of the basket.

Detail of the Model 282 casing jack well head adapter plate

All Casinjacs have well head adapter plates that can be custom machined to fit the most common flanges a customer uses. Here you can see the bolts securing the casing jack to the flange.

Model 282 casing jack trailer unit with Cat C6.6 HPU

Model 282 casing jack - two cylinder operation

Casinjac's symmetrical design allows for 2 speed operation. Two opposing cylinders can be valved off and unpinned. This cuts the lifting force by half, but doubles the cycle time.

casing jack being independently load tested

All of our field service units are load tested by an independent 3rd party to ensure our customers have the safest equipment available on their locations.

Casing Jack being independently load tested

Another picture of the testing. All of our field service units are load tested by an independent 3rd party to ensure our customers have the safest equipment available on their locations.

Pad Eye pull testing

The pad eyes are instrumental in mounting the Casinjac safely. All of our service unit pad eyes are pull tested by and independent 3rd party.

Proactive Safety

Casinjac takes a very proactive to safety, one example is the whip-checks installed on all our field service units.

MODEL 282 CASING JACK FLANGE MOUNTED IN SHALLOW CELLAR

MODEL 282 CASING JACK PULLING PRODUCTION SLIPS

pulled production slips

Many times pulling production slips on a well is beyond the safe operation capacity of the rig. Using a casing jack to pull these slips is a much safer alternative.

MODEL 500 CASING JACK FLANGE MOUNTED IN CELLAR

Model 282 casing jack Rental

We have many sizes of jacks available for rent. We can arrange hot-shot delivery or you can pick them up from our shop with your truck and driver.

BREAKING A COLLAR LOOSE ABOVE A MODEL 500 CASING JACK

Casinjac Model 282 casing jack with our quick response Field Service Truck

Casinjac's small foot print means our casing jacks can be used in tight work spaces.

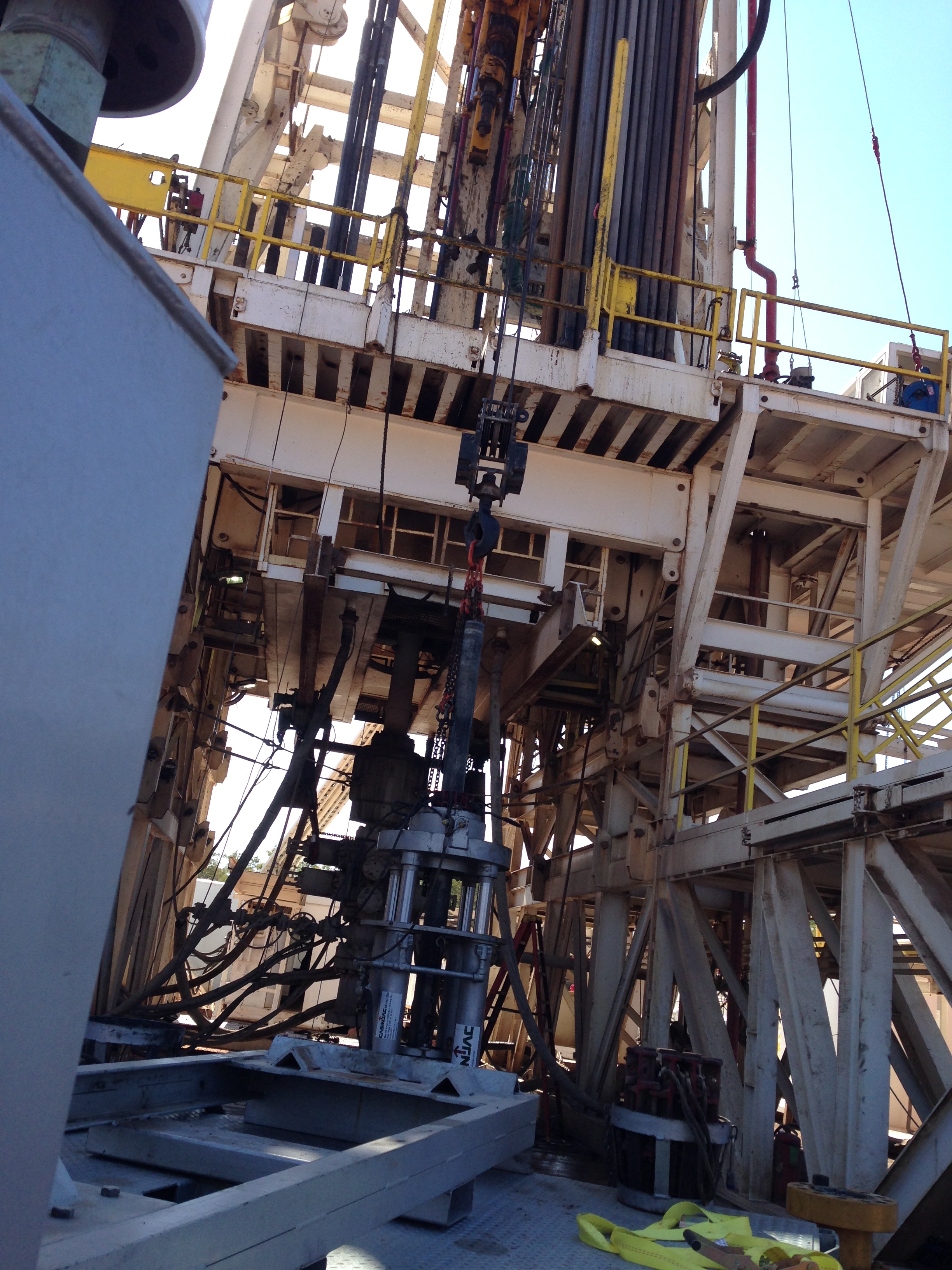

MODEL 282 CASING JACK BEING SET OVER PULL-SUB

Working with the rig crew, a jack can usually be mounted on the flange in 3 to 5 minutes.

TRAILER MOUNTED SERVICE UNIT - MODEL 500 CASING JACK WITH 173HP CAT C6.6 HPU

In addition to our Service Trucks, we have larger field service casing jacks available for maximum pulling power.

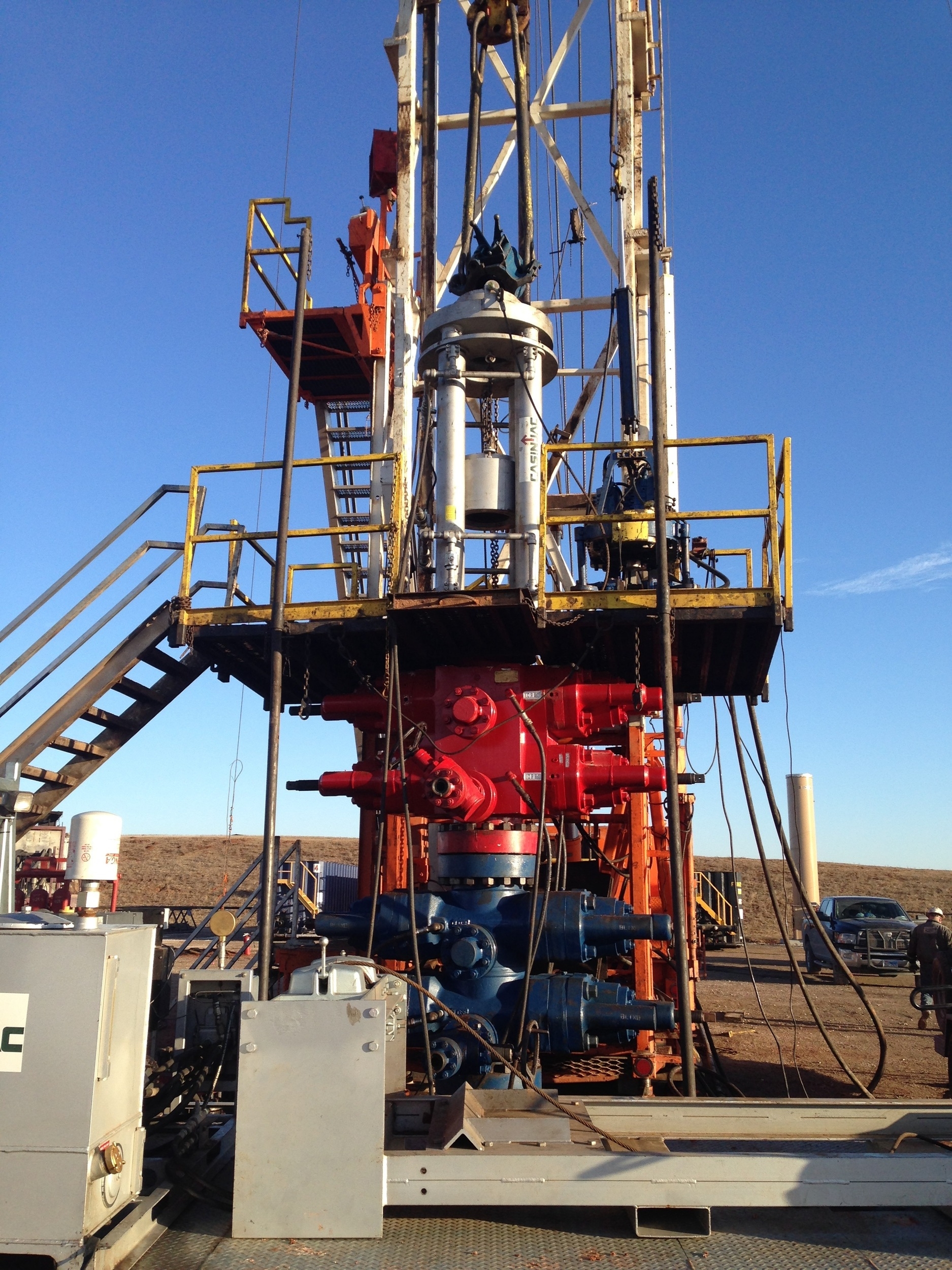

Model 282 casing jack mounted on a BOP.

All Casinjac's have a well head adapter plate designed to bolt the casing jack to a flange or in this case a BOP for added safety.

Model 282 casing jack bottom bowland slips set

All Casinjacs have a bottom bowl assembly that can be lowered in order to set bottom slips. This allows the top bowl to lower and get another "bite" of casing, rasing again and pulling more of the joint free.

field service truck control panel

When working with the huge pulling forces our jacks produce, its important to know exactly how much force the casing is exposed to. Our trucks are equipped with precise digital instruments.

A quick response field service truck arriving on location

casinjac field services out pulling slips

working through a model 282

Sometimes after pulling for a customer, we're asked to stay on the flange in the event the casing has to be pulled through a tight spot. This keeps the rig crew and equipment safe since we're doing the heavy pulling.

Working through the work window on a new, unpainted model 282 casing jack

model 385 casing jack trailer mounted service unit

When larger jobs call for greater pulling power, we have a fleet of service units available to meet your needs.

Removing production slips through a Model 282 casing jack

Casinjacs allow plenty for space for the rig crew to get in and work around the unit.

MODEL 282 CASING JACK WORKING UNDER DRILLING RIG FLOOR

Model 282 casing jack set on drilling rig floor

While drilling rigs have massive pulling capability, a Casinjac has a much more precise and steady pull. This was necessary in this case as the casing was stuck shallow and the customer did not want to risk parting the pipe.

Model 282 casing jack set on drilling rig floor

99hp deere HPU dismounted from service unit

All service units have modular components that can be removed from the trailers and moved closer to the well. This allows for maximum flexibility, no matter how tight the job site is.

model 282 casing jack being set over pull sub

Casinjac first field service unit with Model 282 casing jack

When we reintroduced field services, this was our first unit.